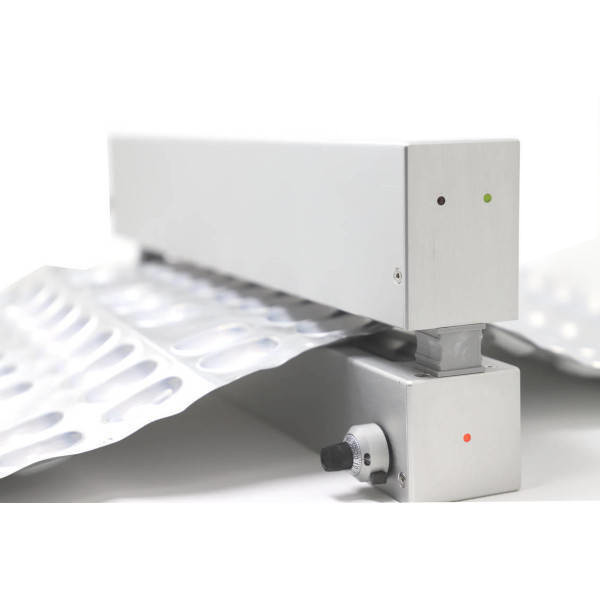

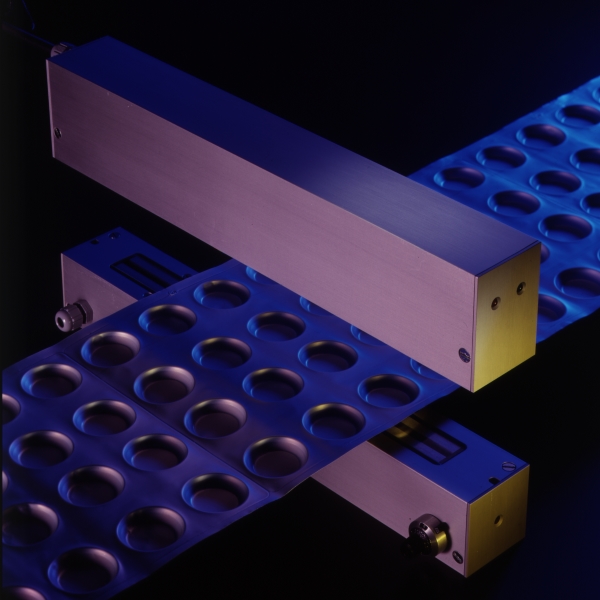

The Nimax – CF118 control system checks the integrity of metal foil by detecting any micro-holes, tears or cracks already present in the foil or produced during deep drawing.

When a defect is found on the foil (lack of opacity), an electrical signal (relay contact) is triggered that is used to reject the affected area.

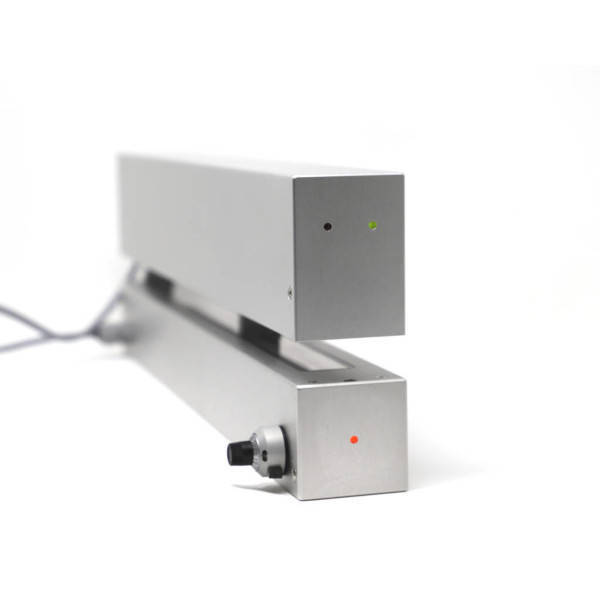

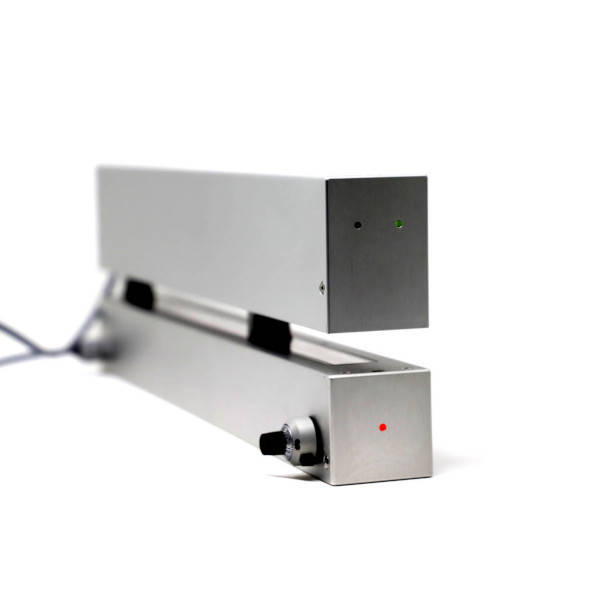

The size of the hole that trips the device (trip threshold) can be set with the sensitivity selector switch on the side of the receiver and can be checked with specific calibrated micro-holes.

Flexible

Many types of strands can be inspected (aluminium, metallic, plastic, etc.)

Easy to incorporate

Can be incorporated in new or retrofit systems.

Sensitive and measurable

Detects micro-holes as small as 0.035 mm.

The performance of the system can be checked with certified gauges.

Fast

The system matches the speeds of the highest performing blister packing machines with operating speeds of up to 150 m/min.

The system consists of:

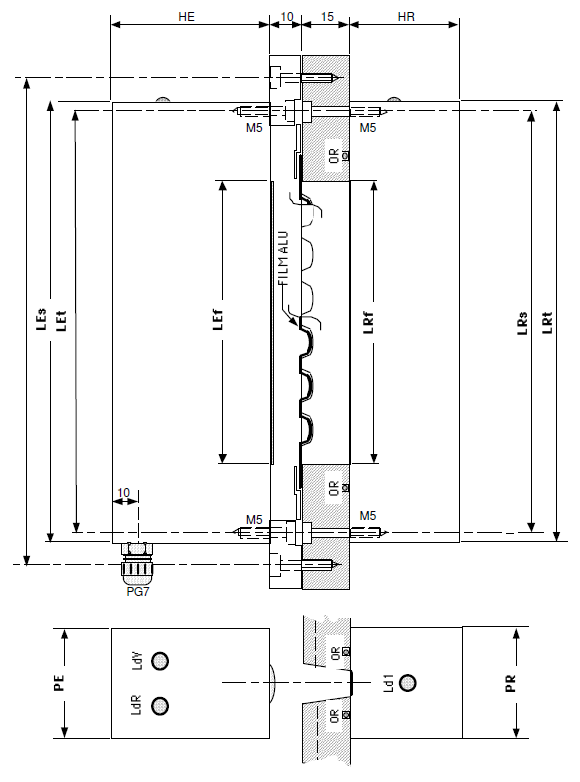

Usually mounted above the foil sliding surface. It generates a row of high intensity infrared light, centred and focused on the foil by a cylindrical lens. The two side support blocks ensure that it is placed at the correct distance. It is independently powered and has an output signal (relay) for alarm in the event of a light circuit fault.

Usually mounted under the foil sliding surface. It consists of a row of light sensors, fitted along the reading axis, as long as the width of the foil to be checked. When it is hit by a light pulse from the illuminator on the top of the foil, the electronic circuit triggers an error signal corresponding to a hole or crack. The receiver must be exactly aligned with the illuminator and completely shielded from external light. With deep-drawn foils, the format manufacturer must provide a guide-support as close as possible to the underside of the film.

A kit containing three gauges with 0.035, 0.050 and 0.100 mm calibrated holes is available on request. They are useful for periodically checking calibration of the receiver.

Premise

“nimax s.p.a.” considers the privacy of its users to be of fundamental importance and guarantees that the processing of personal data is carried out in compliance with the fundamental rights and freedoms, as well as the dignity of the data subject, with particular reference to confidentiality, personal identity and the right to the protection of personal data. In this regard, “nimax s.p.a.” has adopted and implemented a Privacy Policy for everything concerning the management methods of its website (and all the services contained therein) with reference to the processing of users’ personal data.

We therefore ask you to read the following information and to check it periodically, in order to check for any updates or revisions that may become necessary.

The EU Regulation 2016/679 imposes the obligation to inform the interested parties about fundamental elements (specified in Articles 13 and 14), with reference to the processing of the Personal Data concerning them. As far as the undersigned Company is concerned, the Regulation is completely fulfilled by informing you that:

Holder of the treatment

The Data Controller is “nimax s.p.a.“,

Via dell’Arcoveggio, 59/2 – 40129 Bologna (BO)

Tel. 051-4199111

e-mail: privacy@nimax.it

Purpose of the processing

Any data acquired, always in compliance with the current legislation, will be processed for institutional purposes, connected and / or instrumental to the provision of access to this website, including any additional services requested by the user, in particular:

Types of data processed

– Navigation data –

The computer systems and software procedures used to operate this website acquire, during their normal operation, some personal data whose transmission is implicit in the use of the Internet communication protocols.

These information are not collected to be associated with identified interested parties, but by their very nature could, through processing and association with data held by third parties, allow users to be identified.

These data are used only to obtain anonymous statistical information on the use of the website and check its correct functioning and are deleted immediately after processing. The data could be used to ascertain responsibility in case of hypothetical computer crimes against the website.

– Data provided voluntarily by the user –

The optional, explicit and voluntary sending of personal data to this site, through the appropriate fillable forms, as well as the other contact channels indicated, entails the subsequent acquisition of the sender’s e-mail address, necessary to respond to requests, and of the other personal data possibly communicated on the basis of the requested service.

Methods of processing and data retention period

Your personal data will be processed with the aid of digital or paper supports, always in full compliance with the principles of security and confidentiality. Your personal data will be kept for the period necessary to fulfill the purposes for which they were collected or until your explicit request for cancellation (see paragraph “Rights of interested parties”). Throughout the retention period, your personal data will always be stored in compliance with the applicable legislation.

Dissemination of personal data

Your personal data will not be disclosed, with this term meaning the disclosure of it to indeterminate subjects in any way, including by making them available or consulting. Furthermore, it is guaranteed that the treatment of data is carried out by minimizing the use of personal data and identification data, limiting their use to cases where they are strictly necessary to achieve the purposes for which they were collected.

“nimax s.p.a.” also guarantees the adoption and observance of specific security measures to prevent the loss of data and any illicit or incorrect use of the same.

Scope of

The management methods, listed below, refer to this website, in relation to the processing of personal data of users who consult it and interact with the services and web pages accessible electronically from the address:

corresponding to the home page of the website.

The information is provided exclusively in relation to the website in question and its parts and cannot be extended to other websites or pages not belonging to the site itself (including those that can be consulted by the user via direct links from this site).

In particular, on this site there are links to some social networks: Linkedin, Facebook, Youtube. This information is not extendable even to those websites, by entering which the user relieves the Owner of any responsibility. To consult the privacy policy of those companies, the user is requested to visit the related websites:

LinkedIn: https://it.linkedin.com/legal/privacy-policy?_l=it_IT

Facebook: https: // www. facebook.com/privacy/

YouTube: https://support.google.com/youtube/answer/2801895?hl=it&ref_topic=9386940

Rights of interested parties

According to the provisions of Articles 15-22 of EU Regulation 2016/679, the subjects to whom the personal data refer have the right to:

You can exercise these rights by contacting the Data Controller directly through the contact channels previously indicated in the paragraph “DATA CONTROLLER”.